There are many occasions when a standard product won't quite do the job you have to produce, or you can't see anything to help you with a problem you may have. Premier offer a service for the design and manufacture of special cutting tools to customer requirements, which are available on short lead times.

Premier can offer you the following:

These are a few examples of some of the many special tools we have made to customers' requirements

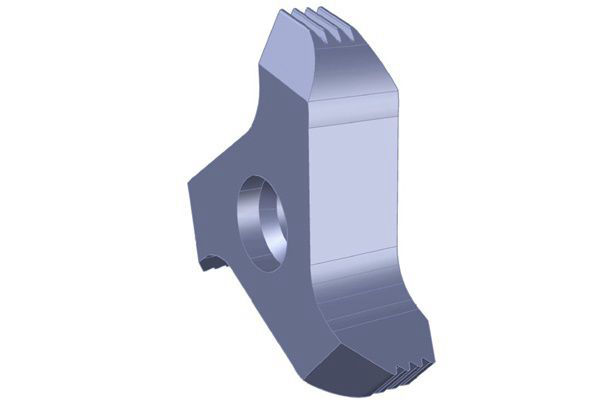

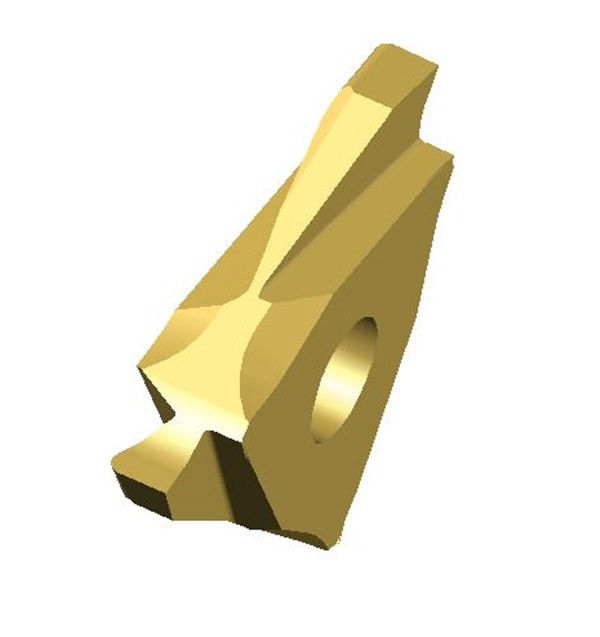

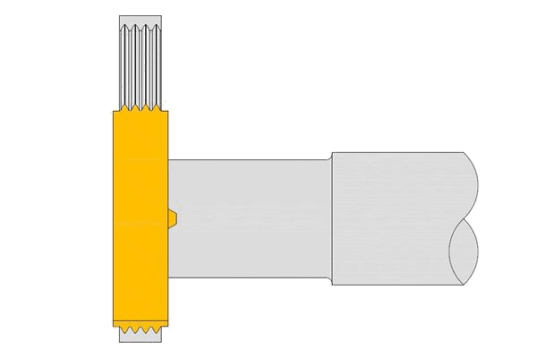

A special multi-tooth spline milling insert

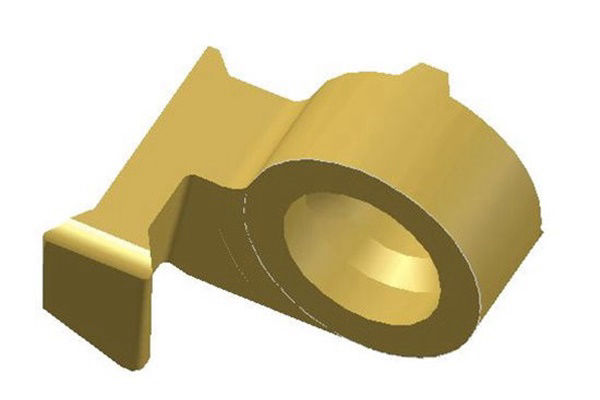

A special ø4 small cone boring insert

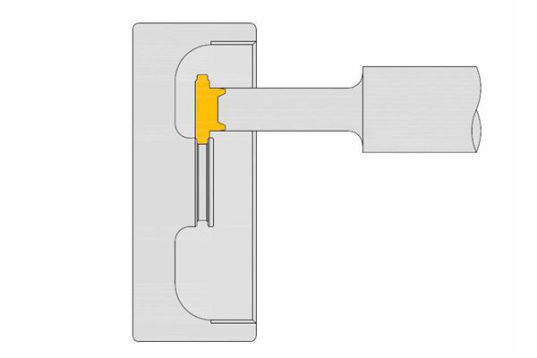

A special D14 face grooving insert to groove behind an internal thread

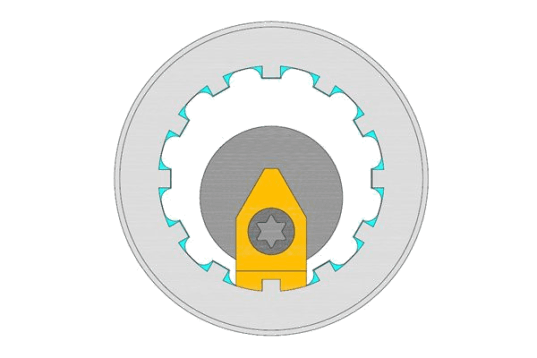

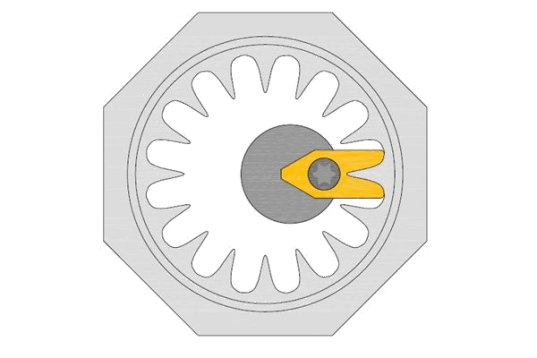

A special spur gear milling cutter

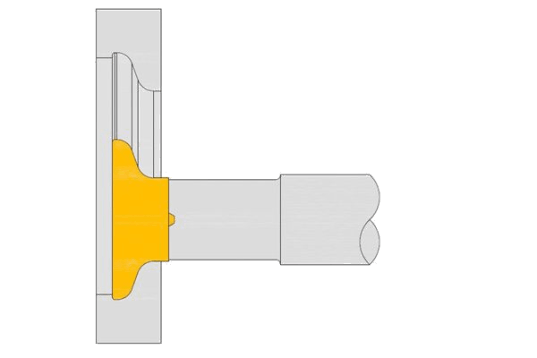

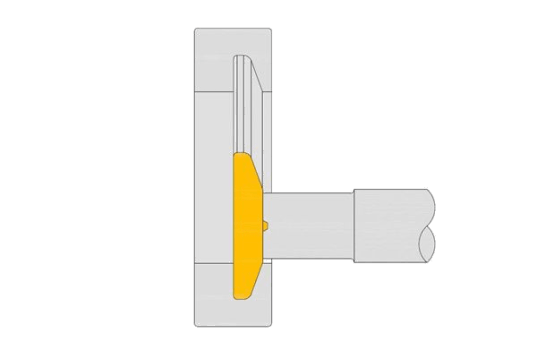

A special form milling cutter to produce a form detail inside a bore

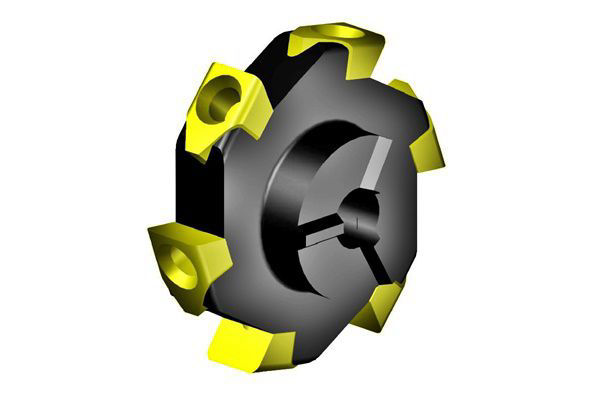

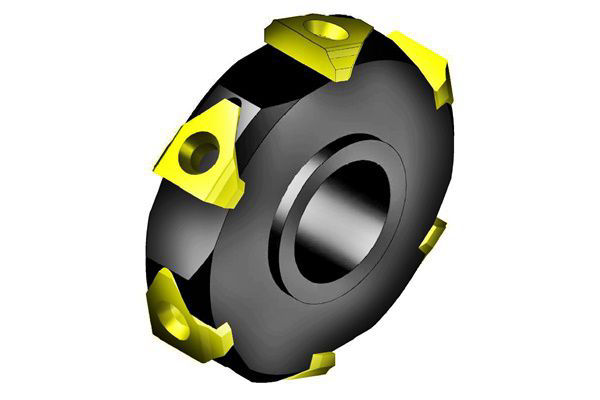

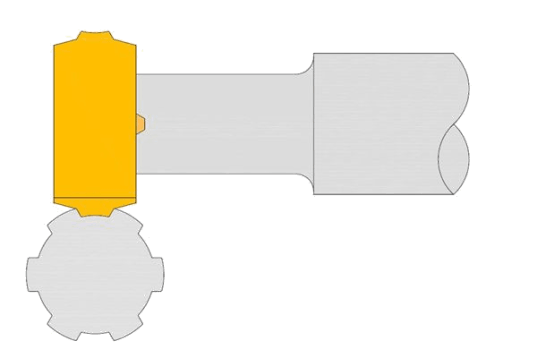

A special ø30 cut dia 6 tooth tangential milling cutter with 6mm wide inserts to fit onto a standard carbide V28 toolholder

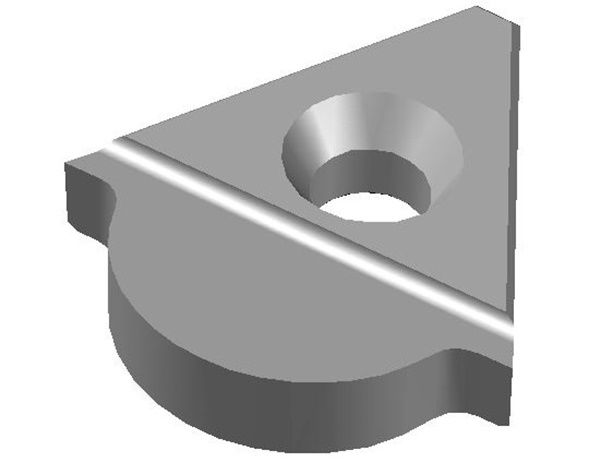

A special V28 groove milling insert with 4 forms for producing a detail inside a component

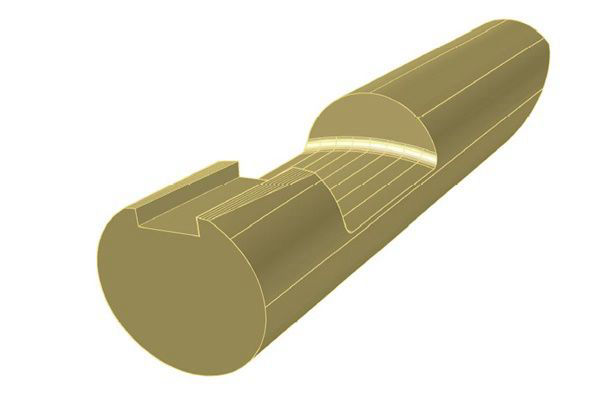

A ø10 solid carbide internal slotting tool for producing an upstanding key inside a ø13mm bore

A special MTM solid carbide thread milling cutter ground to produce a 2BA thread

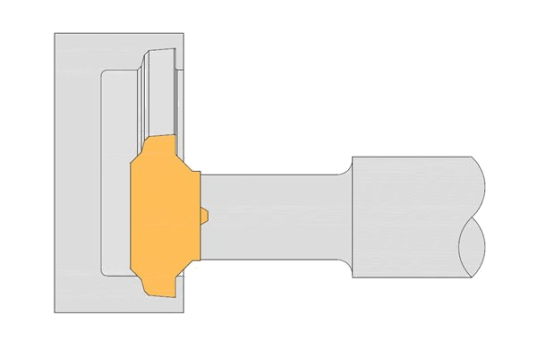

A special ø100 cut dia 6 tooth tangential milling cutter with 18mm wide special form inserts for producing an internal groove detail

A special A10 twin tooth slotting insert for producing a series of 1mm wide x 0.65mm deep slots inside a ø10.4mm bore

A special ø10mm Tap-X thread mill to produce a conduit thread

A special E12 grooving insert ground to produce a half dovetail seal groove

A special D18 face grooving insert to rough and finish a dovetail seal groove

A special F12 form insert ground to produce a 20mm pitch rope thread

Special Carbide Cutting Tools

Some machining operations require more than a standard tool. Premier Form Tools manufactures special carbide cutting tools designed specifically for your component, material, and process.

Custom tooling for your application

We can design and manufacture:

Special form tools

Combination tools

Profile tools

Non‑standard diameters and lengths

Tools to replace multiple operations with one

How the process works

Discuss your application – Send us your drawing, sample, or specification.

Tool design – We propose a tool geometry to meet your requirements.

Manufacture – The tool is produced using precision grinding.

Approval and repeat supply – Once proven, we can supply repeat batches as needed.

Benefits of special tools

Reduced cycle times

Improved accuracy and repeatability

Fewer tool changes

Better process reliability

Please let us quote you for your requirements - just Email a drawing and details of what you would like to enquiries@premierformtools.co.uk

............................................

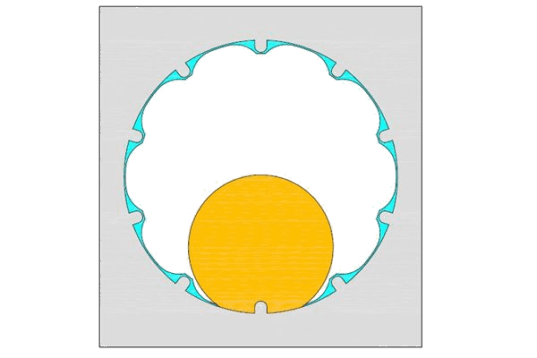

A special 10mm wide F10 broaching insert to produce the finished detail from the rough milled outline shown in light blue inside a ø35mm bore

A special ø10mm A10 slotting insert designed to finish the curved top upstands from the rough milled outline shown in light blue inside a ø17mm bore

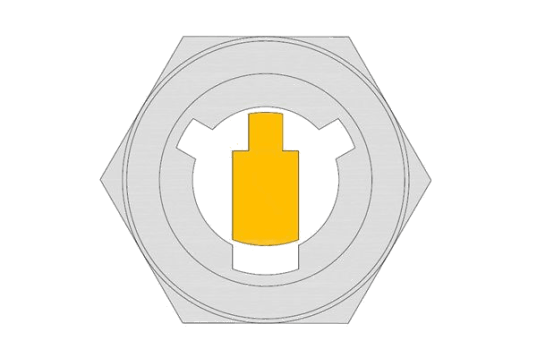

A special ø6.6mm A10 twin tooth slotting insert designed to produce orientation slots of two different widths from solid inside a ø7.2mm bore

A special D16 broaching insert designed to produce an internal spline form from solid inside a ø20mm bore

A special D16 slotting insert designed to produce 3 varying width connector location slots from solid inside a ø21.19mm bore

A special toolholder and 12mm wide F12 slotting insert to produce an internal location form from solid inside a ø41mm bore

............................................

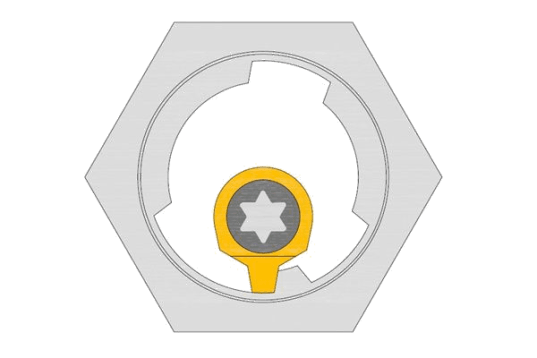

A special ø9.7mm cut diameter P10 groove milling insert designed to produce an O ring groove on an internal spigot

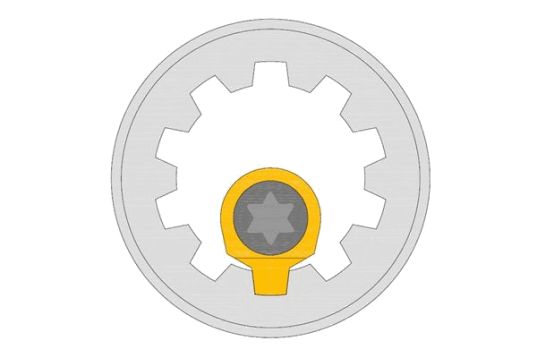

A special ø27.7mm cut diameter V28 groove milling insert designed to produce a grip finish inside a ring

A special ø27.7mm cut diameter V28 groove milling insert designed to produce an internal seal groove

A special ø21.7mm cut diameter V22 groove milling insert designed to produce an external spline form on a shaft

A special ø31.7mm cut diameter V32 insert designed to produce an internal undercut

A special ø21.7mm cut diameter V22 groove milling insert designed to produce an internal seal groove

Premier Form Tools

Manufacturers of Precision Ground Carbide Cutting Tools

Serving engineering, aerospace, automotive, medical, and precision machining industries.

Mobirise.com